Operating principle of LGB Annubar Flow Meter is the same as that of other kinds of differential pressure flow meters, Annubar Flow Meter is superior to other differential pressure flow meters because of its unique structure.

Made in China. brand DDTOP, model LGB

Fast delivery to Latvia, Estonia and Lithuania. International delivery to Europe, Asia, Africa and other continents available on request

Our warehouse is located in Riga, Latvia.

price by request

Available

Official distributor in Latvia

Time-tested American, European and Asian brands of control and measurent instruments

Special price list for organisations

We offer a significant discount for trade organisations and manufacturing companies

Worldwide shipping on request

We take care of all logistics and customs clearance. Fast delivery to Baltic countries

After-sales service and support

Warranty service and repair, expert assistance in the operation of the instruments

Because of the wide variety of flow measurement techniques and instrumentation types, and the complexity of the objects being measured, flow measurement instrumentation is technically complex to apply. It is very different from the traditional application of metrology measuring instruments – it is not simply to install the flowmeter, open the meter to run will necessarily be able to achieve the purpose of measurement. As most of the flow meters are medium contact type, it is necessary to ensure the safe operation of the instrument on the basis of the instrument, and strive to improve the accuracy of the measurement instrument and energy saving. This is not only to select flow meters with the required accuracy, but also to select a reasonable measurement method according to the characteristics of the measured medium.

Operating Principle

The principle of operation of an Annubar Flow Meter is the same as that of other differential pressure flowmeters, which is based on the principle of energy conservation in a sealed pipe. However, due to its unique structural design, the Annubar Flow Meter offers the following advantages.

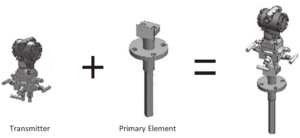

Flow Meter Components

The Annubar Flow Meter consists of a primary choke (sensing) element, a transmitter, and a valve unit.

Measurement Principle

The Annubar Flow Meter is a differential pressure flow meter. Flow instruments based on the differential pressure principle have been in use for more than a hundred years so far. The differential pressure principle is based on the principle of energy conversion in a sealed pipe, which means that for a stable fluid, the flow rate is proportional to the square root of the flow rate of the medium in the pipe. As we know, the pressure decreases as the velocity increases. When the medium is close to the throttle, the pressure is P1; when the medium goes through the throttle area, due to the medium circulation area decreases, so the flow rate will increase, the pressure decreases to P2. When the flow rate changes, the differential pressure value between the two pressure ports of the flow meter will increase or decrease. When the flow rate is constant, if the throttling area is large, the resulting differential pressure will be large.

Features

1.Unique rhombic monolithic double-cavity structure avoids the chamber leakage or fracture caused by the multi-piece structure or welding process of other forms of sensors and increases the overall strength of the sensor part;

2.It can measure many kinds of medium, such as dry or moist gas, vapor, liquid, etc.

3.Probe materials have special 1.4528 and ha C4 alloys, specifically for a variety of strong corrosion medium;

4.Good plugging performance

5.It can be measured in both directions

6.Small permanent pressure loss, about 3% of the full scale differential pressure value

7.It can directly measure the temperature and pressure of the medium, calculate the mass flow rate of vapor and gas and the standard flow rate

8.Resistance (sensor) components and transmitters are all universal, free exchange, save spare parts costs. Intelligent, with HART communication protocol, can be remote configuration and calibration function.

Applications

Electricity Industry: Desalination Tanks

| Model | Economical threaded connection | Economical flange connection | Accuracy Pipelined | ||

| Accuracy | ±1.0% | ±0.5% | |||

| Repeatability | ±0.2% | ||||

| Range Ratio | Usually 10:1, special cases depending on parameters | ||||

| Requirements for Straight Pipe | Usually 8D in front, 4D in back. | ||||

| Suitable Sensor Type | Reynolds number >6500, No.05 probes.

Reynolds number >12500, No.10 probes. Reynolds number >25000, No.20 probes |

||||

| Pressure Loss | Differential pressure value of 3%, calculated | ||||

| Size | DN50-1800 | ||||

| Temperature | Integral installation up to 260°C Split type installation up to 400°C | ||||

|

Flange Standard

|

ANSI B16.5

HG20592 |

ANSI B16.6 | |||

| Pressure | 150#-1500# | 150#-1500# | |||

| Pressure Extraction Method | Thread, Socket Weld, Coplanar Flange | ||||

| Medium | Gases, Liquids, Vapors | ||||

| Applicable Situations | Medium/low pressure, conventional applications | High /medium/low pressure, conventional applications | Small diameter, where precise measurement is required | ||

Note:

| LGB-C | Annubar Flow Meter | ||||||

| Process

Connection |

01 | Process Connection | |||||

| 02 | Double-sided support type with threaded connection | ||||||

| 03 | Flange connection type | ||||||

| 04 | Double-sided support type with flange connection | ||||||

| Sensor Mode | A | Type A Sensor(Suitable to Size DN50-DN200) | |||||

| B | Type B Sensor(Suitable to Size DN150-DN900) | ||||||

| C | Type C Sensor(Suitable to Size DN300-DN1800) | ||||||

| Sensor Material | S | S316L | |||||

| A | alloy steelSpecial materials (to be specified) | ||||||

| E | |||||||

| Pipe | DN XXX | Pipe XXX | |||||

| Pipe Material | CS | Carbon Steel | |||||

| S1 | SS304 | ||||||

| S2 | SS316 | ||||||

| C5 | 15CrMo | ||||||

| 00 | Special materials (to be specified) | ||||||

| Pressure Port | R | Threaded connections, openings on both sides | |||||

| RS | Socket welded, openings on both sides | ||||||

| P | Threaded connection, opening end up | ||||||

| PS | Socket weld, open end up | ||||||

| F1 | Direct standard (connected to a Tri-valve manifold) | ||||||

| LGB-G | Annubar Flow Meter | |||||||

| Process Connection | S | Flat welded flange | ||||||

| W | Butt welded flange | |||||||

| H | Straight welding (flangeless) | |||||||

| Sensor Mode | A | Type A Sensor(Suitable to Size DN50-DN200) | ||||||

| B | Type B Sensor(Suitable to Size DN150-DN900) | |||||||

| C | Type C Sensor(Suitable to Size DN300-DN1800) | |||||||

| Sensor Material | S | S316L | ||||||

| A | alloy steel | |||||||

| E | Special materials (to be specified) | |||||||

| Pipe Size | 05 | DN50 | ||||||

| 08 | DN80 | |||||||

| 10 | DN100 | |||||||

| – | – | |||||||

| Nominal pressure | 150 | ANSI B16.5 150#Flange RF sealing surface | ||||||

| 300 | ANSI B16.5 300# Flange RF sealing surface | |||||||

| 600 | ANSI B16.5 600# Flange RJ sealing surface | |||||||

| Pipe Material | CS | Carbon Steel | ||||||

| S1 | SS304 | |||||||

| S2 | SS316 | |||||||

| C5 | 15CrMo | |||||||

| 00 | Special materials (to be specified) | |||||||

| Pressure Port | R | Threaded connections, openings on both sides | ||||||

| RS | Socket welded, openings on both sides | |||||||

| F1 | Direct standard type | |||||||

| F3 | Coplanar standard type | |||||||

| □ | □ | □ | □ | □ | □ | □ | □ | |

Example

LGB-GSAS05 150CSR: Annubar Flow Meter; Process Connection: Flat Welded Flange; Sensor Type: Type A; Sensor Material: 316L; Piping size: DN50; Nominal Pressure: CL150#; Sealing Surf: RF; Pipe Material: Carbon Steel; Pressure Port: Threaded; Openings: On Side.

You can request the necessary certificates, documentation, instructions and user guide for DDTOP LGB using the special form.

You can buy DDTOP LGB in Latvia at a favourable price in «OLIL SIA» by leaving a request on the website, by phone +371 672 70580 or by email olil@olil.lv. DDTOP LGB price are subject to change depending on exchange rates. We deliver instruments by transport companies in Latvia, Estonia and Lithuania. Worldwide shipping to Europe, Asia, Africa, North and South America available on request.

See also: Acid flow meters, Chemical flow meters, Digital flow meters, Explosion proof flow meters, Flow meters, Flow meters 4 20ma, Flow meters for large pipes, Flow meters with analog output, Flow meters with hart protocol, Fuel & oil flow meters, Gas & air flow meters, High pressure flow meters, Hydrogen flow meters, Insertion flow meters, Liquid & water flow meters, Mass flow meters, Nitrogen gas flow meters, Oxygen flow meters, Smart flow meters, Stainless steel flow meters, Steam flow meters