Artang’s Exclusive Offer: 2-YEAR WARRANTY. That’s twice the industry standard for electromagnetic flowmeters!

Analogue of Endress Hauser Dosimag D5AB and Krohne BATCHFLUX 5500.

Made in China. brand ARTANG, model Aimag G

Fast delivery to Latvia, Estonia and Lithuania. International delivery to Europe, Asia, Africa and other continents available on request

Our warehouse is located in Riga, Latvia.

Retail price from 1800 €

Available

Official distributor in Latvia

Time-tested American, European and Asian brands of control and measurent instruments

Special price list for organisations

We offer a significant discount for trade organisations and manufacturing companies

Worldwide shipping on request

We take care of all logistics and customs clearance. Fast delivery to Baltic countries

After-sales service and support

Warranty service and repair, expert assistance in the operation of the instruments

Aimag G is designed for demanding filling and bottling applications with conductive liquids in Food & Beverage and Life Sciences. In applications where space is limited, Aimag G is the preferred choice for system integrators, skid builders and equipment manufacturers. Aimag G measures volume directly. The bidirectional measuring principle is virtually independent of pressure, density, temperature and viscosity.

Flow rate limit:

The nominal diameter of the sensor depends on the inner diameter of the pipe and the flow rate of the medium. The optimal flow rate is between 1 and 2 m/s. In addition, the flow rate must match the physical properties of the fluid.

The instrument can be installed anywhere on the running pipe, preferring vertical installation. When measuring, it is necessary to ensure that the measuring tube is completely filled with medium, and the electromagnetic flowmeter does not work properly in the case of non-full tube. The flow direction of the medium in the pipe should match the arrow pointing on the sensor. When lifting the meter, avoid inserting a pipe or basket into the measuring tube or using a rope to lift it to avoid damaging the lining. Instead, loop the rope around the neck of the measuring tube for lifting. Do not install measuring equipment in the pipeline downstream of the filling valve. When the measuring equipment is completely empty, the measured value will be severely distorted.

Measurement principle:

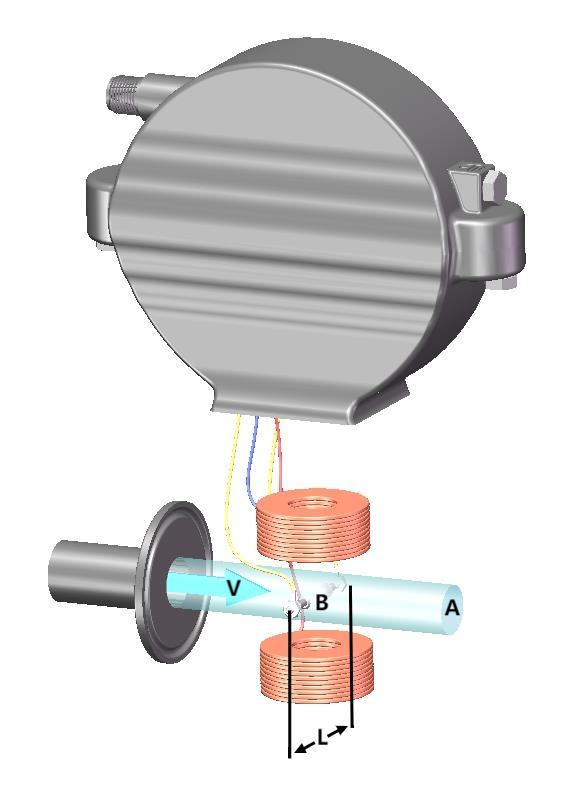

The measurement principle of an electromagnetic flowmeter is based on Faraday’s law of electromagnetic induction, and the movement of a conductor in a magnetic field will generate an induced voltage.

The electromagnetic flowmeter generates a constant alternating magnetic field through the switching direct current I with alternating polarity, and the direction of the magnetic field is perpendicular to the direction of medium flow. During flow measurement, the medium flows through the magnetic field, and the flowing medium is equivalent to a moving conductor, which induces an electromotive force Ue proportional to the flow velocity of the medium.

Ue = B*L*v

B: Magnetic strength

L: Electrode spacing

V: Medium flow rate

The electromagnetic flowmeter detects the induced electromotive force through two measuring electrodes and transmits it to the converter for processing. Based on the cross-sectional area A of the measuring pipe, the volume flow Q of the fluid can be calculated: Q = A·v

Product features:

Application:

| Measuring Principle | Electromagnetic |

| Accuracy | ±0.2% |

| Sizes | DN8, DN10, DN12, DN15, DN25 |

| Liner | PFA (-20℃~150℃) |

| Electrode | 316L; Hastelloy C; Tantalum; Titanium; Platinum |

| Process Connection | Tri-Clamp; Welding connection DIN 11850 |

| Material | Full Stainless Steel Housing ; EPDM/Viton Sealing Rings |

| Max. Process Pressure | PN 16 |

| Protection Grade | IP67 |

| Wetted Parts Surface Finish | ≤0.8 μm |

| Power Supply | 18-28VDC |

| Output Signal | Pulse / Frequency / Switch / Status, Modbus RS485 |

| Ambient temperature | -40~60℃ |

| Relative humidity | 5%~95% |

| Storage temperature | The storage temperature is consistent with ambient temperature |

| Medium conductivity | ≥ 5 μ S/cm, conventional conductive liquid |

You can request the necessary certificates, documentation, instructions and user guide for ARTANG Aimag G using the special form.

You can buy ARTANG Aimag G in Latvia at a price starting from 1800 € in «OLIL SIA» by leaving a request on the website, by phone +371 672 70580 or by email olil@olil.lv. ARTANG Aimag G price are subject to change depending on exchange rates. We deliver instruments by transport companies in Latvia, Estonia and Lithuania. Worldwide shipping to Europe, Asia, Africa, North and South America available on request.