Products not found

Select the Series 2000 Magnehelic® Gage for a versatile low differential pressure gage with a wide choice of 81 models and 27 options to choose from. Using Dwyer’s simple, frictionless Magnehelic® gage movement, it quickly indicates air or noncorrosive gas pressures–either positive, negative (vacuum) or differential. The design resists shock, vibration, over-pressures and is weatherproof to IP67. Select the -HA High Accuracy Magnehelic® Gage option for an accuracy within 1% of full scale, located below in the Product Configurator. Also included with the –HA option at no extra cost is a mirrored scale overlay and a 6 point calibration certificate.

Retail price from 75.35 €

The Series 4000 Capsuhelic® Differential Pressure Gage is designed to give fast, accurate indication of differential pressures. The gage may be used as a readout device when measuring flowing fluids, pressure drop across filters, liquid levels in storage tanks and many other applications involving pressure, vacuum or differential pressure. The pressure being measured is held within a capsule which is an integral part of the gage. This containment of the pressure permits the use of the gage on system pressures of up to 500 psig, even when differentials to be read are less than 0.1 in w.c.

Retail price from 772.7 €

The Series PTGD Differential Pressure Piston-Type Gage can be used to measure the pressure drop across filters, strainers, pump performance testing, and heat exchanger pressure drop monitoring. Its simple, rugged design possesses weather and corrosion resistant gage front with a shatter resistant lens. The Series PTGD contains a piston-sensing element which provides different differential pressure ranges with full-scale accuracies of ±2%. Constructed with aluminum or 316SS and available with two 1/4″ female NPT end connections, the Series PTGD provides over-range protection rated to 3000 psig (200 bar) or 6000 psig (400 bar) depending on model. Standard models come with in-line connections. Back or bottom connections are also available.

Retail price from 254.6 €

The Series PFG2 Process Filter Gage is designed for determining the state of an inline filter. The differential pressure indicator determines the pressure drop on either side of a filter through its 1/8″ female NPT pressure connections, and relates the value to one of three zones: clean (green), change (yellow), or dirty (red). The Series PFG2 is perfectly suited for filter applications, line loss, valve drop, and many other differential pressure applications where a simple indicator is needed. The direction of process flow is indicated on the dial, with the arrow pointing to the low pressure port. The PFG2 can be connected in-line through the side process connections, but can also be directly mounted through the outlet/inlet.

Retail price from 98.5 €

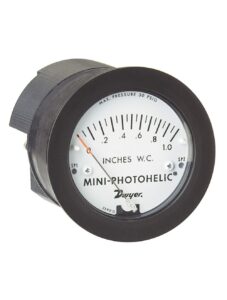

The Series MP Mini-Photohelic® Differential Pressure Switch/Gage combines the time proven Minihelic® II differential pressure gage with two SPDT switching set points. The Mini-Photohelic® switch/gage is designed to measure and control positive, negative, or differential pressures consisting of non-combustible and non-corrosive gases. Gage reading is independent of switch operation. Switching status is visible by LED indicators located on the front and rear of the gage. Set points are adjusted with push buttons on the back of the unit.

Retail price from 501.3 €

Bourdon tube pressure gauges aluminium case DS 10” (250 mm)

These instruments are designed for use in chemical and petrochemical processing industries, and in conventional power plants, built to resist the most severe operating conditions, to measure gaseous or liquid media which do not have high viscosity or do not crystallize.

price by request

Bourdon tube pressure gauges with microswitch, DS 4” (100mm)

These instruments are designed for applications in conventional power stations. They safety control the automatic regulation of hydraulic and pneumatic equipment.

price by request

Bourdon tube pressure gauges all stainless steel construction DS 1.5”, 2” (40-50 mm)

These instruments are designed for use in chemical and petrochemical processing industries, and in conventional power plants, to measure gaseous or liquid media which do not have high viscosity or do not cristalize. They are built to resist the most severe operating conditions created by the ambient environment and the process medium. For use on power units, pumps, hydro-cleaning machines, presses, engine compressors, turbines, diesel engines, chemical, petrochemical and refrigerating plants and on machines and equipment where pulsating pressures or mechanical vibrations are apparent, the liquid-filled version is recommended.

price by request

Pressure gauges with electric contacts DS 4” (100mm)

They are used to control the electrical operation of compressors, pumps, presses, hydraulic and pneumatics equipment. The contacts open or close the circuit depending on the position of the indicating pointer and they are adjustable over the whole range. For application on severe working conditions, such as rapid and frequent pressure change, vibration and pulsation, they are manufactured with the case liquid filled. The filling drastically reduces the effect of such factors as well as those caused by a corrosive atmosphere, giving longer life and better performances of the pressure gauge and their electric contacts. They are also available with inductive contacts intrinsecally safe.

price by request

Bourdon tube pressure gauge all stainless steel construction DS 2.5” (63mm)

These instruments are designed for use in chemical and petrochemical processing industries, and in conventional power plants, to measure gaseous or liquid media which do not have high viscosity or do not cristalize. They are built to resist the most severe operating conditions created by the ambient environment and the process medium. For use on power units, pumps, hydro-cleaning machines, presses, engine compressors, turbines, diesel engines, chemical, petrochemical and refrigerating plants and on machines and equipment where pulsating pressures or mechanical vibrations are apparent, the liquid-filled version is recommended.

price by request

Pressure gauges with electric contacts DS 4”, 6” (100-150 mm)

Alarm contacts are accessories with movable contacts in air, which open or close electric circuits depending of the position of the indicating pointer. They are used with Bourdon tube pressure gauges, bellows, diaphragm and thermometers of NUOVA FIMA production, in such way they become pressure and temperature switches: the optimal and sure solution to automatize any kind of equipment.

price by request

Bourdon tube pressure gauges all stainless steel construction DS 4”, 6” (100-150mm)

These instruments are designed for chemical, petrochemical industries and for conventional power plants. They are built to resist to the most severe conditions created by the process medium and by the environment and for those fluids, which have high viscosity and do not crystallize. The quality of the materials used to build the sensible element allows their use with high frequency pulsating pressures.

The TIG welding between the case and the process socket, strengthens the instrument and assures better containment of dampening fluid. The advantages of filling the case of the instrument with a dampening fluid are: reduced pointer fluctuation, reduced wear of rotating parts of the movement when pulsant vibrations and pulsations occur. Moreover condensation and corrosive atmospheres which could damage the internal parts are prevented.

price by request

Bourdon tube pressure gauges all stainless steel construction, with microswitch, DS 4” (100mm)

These instruments are designed for applications in the chemical, petrochemical industries, conventional power stations. They safety control the automatic regulation of hydraulic and pneumatic equipment.

price by request

Bourdon tube ”solid-front“ pressure gauges all stainless steel construction DS 2.5” (63mm)

These Solid-Front instruments are built in accordance with safety specifications of EN 837-1 “S3” and ASME B40.1.

The safety construction consists of a solid separating wall in stainless steel, placed between the scale and the elastic element and a blow out back which is released from the case whenever an internal pressure, due to leaks, is created or the elastic element is broken. A leak tight fit is ensured if the instrument is filled with a dampening fluid to prevent damage due to vibration. These instruments are designed for use in chemical and petrochemical processing industries, and in conventional power plants. They are built to resist the most severe operating conditions created by the ambient environment and the process medium.

price by request

Pressure gauges with electric contacts all stainless steel construction DS 4” (100mm)

They are used to control the electrical operation of compressors, pumps, presses, hydraulic and pneumatics equipment, chemical and petrochemical plant. The contacts open or close the circuit depending on the position of the indicating pointer and they are adjustable over the whole range. For application on severe working conditions, such as rapid and frequent pressure change, vibration and pulsation, they are manufactured with the case liquid filled. The filling drastically reduces the effect of such factors as well as those caused by a corrosive atmosphere, giving longer life and better performances of the pressure gauge and their electric contacts. They are also available with inductive contacts intrinsecally safe.

price by request

Safety pressure gauges ”solid-front“ all stainless steel construction DS 4”, 6” (100-150mm)

These instruments are built in conformity with the construction and safety specifications of EN 837-1/S3 e ASME B40.1.

In case of leaks or break of the elastic element, the operator is protected by a solid separating wall placed on the front of the instrument and by the blow out back. They are usually used in the chemical, petrochemical industries and in conventional and power plants. The TIG welding between the case and the process socket, strengthens the instrument and assures a better tight in case of dampening fluid. The advantages of filling the case of the instrument with a dampening fluid are: reduced pointer fluctuation, reduced wear of rotating parts of the movement when pulsant vibrations and pulsations occur. Moreover condensation and corrosive atmospheres which could damage the internal parts are prevented.

price by request

Pressure gauges with electric contacts all stainless steel execution DS 4”, 6” (100-150 mm)

Alarm contacts are accessories with movable contacts in air, which open or close electric circuits depending of the position of the indicating pointer. They are used with Bourdon tube pressure gauges, bellows, diaphragm and thermometers of NUOVA FIMA production, in such way they become pressure and temperature switches: the optimal and sure solution to automatize any kind of equipment.

price by request

Bourdon tube pressure gauges HEAVY WORK DS 4”, 6” (100-150mm)

These instruments are designed for use in chemical and petrochemical processing industries, and in conventional power plants.

They are built to resist the most severe operating conditions created by the ambient environment and the process medium. The high strength of the sensing element makes these instrument suitable to withstand high overpressure up to 4 times the full scale value and together with the case filling, they are suitable to high dynamic pulsating pressure. An Argonarc welded case/socket strengthens the whole construction.

price by request

Pressure gauges with electric contacts all stainless steel construction DS 6” (150mm)

These instruments are manufactured in accordance with the safety norms prescribed by UNI 8541, DIN 16006 e ANSI B40.1. They are used to control the electrical operation of compressors, pumps, presses, hydraulic and pneumatic equipments, chemical and petrochemical plant. In the event of leakage or break of sensing element, the operator is protected by a solid baffle wall placed on the instrument front and by the rear blow out wall. The contacts open or close the circuit depending on the position of the indicating pointer and they are adjustable over the whole range. For application on severe working conditions, such as rapid and frequent pressure change, vibration and pulsation, they are manufactured with the case liquid filled. The filling drastically reduce the effects of such factors as well as those caused by the corrosive atmosphere, making longer life and better performances of the pressure gauge and their electric contacts. They are also available with inductive contacts intrinsically safe.

price by request

Bourdon tube “solid-front” pressure gauges HEAVY WORK DS 4”, 6” (100-150mm)

These instruments are designed for use in chemical and petrochemical processing industries, and in conventional power plants.They are built to resist the most severe operating conditions created by the ambient environment and the process medium. The high strength of the sensing element makes these instrument suitable to withstand high overpressure up to 4 times the full scale value and together with the case filling, they are suitable to high dynamic pulsating pressure. An Argonarc welded case/socket strengthens the whole construction. The solid-front version of these instruments is built in accordance with safety specifications of EN 837-1 and ASME B40.1. The safety construction consists of a solid separating wall in stainless steel, placed between the dial and the elastic element and a blow out back which is released from the case whenever an internal pressure, due to leaks, is created or the elastic element is broken.

price by request

Bourdon tube pressure gauges DS 6” (150mm)

They can be used with gaseous or liquid media which do not corrode copper alloy and which do not have high viscosity or do not cristalize.

price by request

Safety pressure gauges ”solid-front“ all stainless steel construction for high pressures, DS 4”, 6” (100-150mm)

These instruments are built in conformity with the construction and safety specifications of EN 837-1/S3 e ASME B40.1.

In case of leaks or break of the elastic element, the operator is protected by a solid separating wall placed on the front of the instrument and by the blow out back. They are mainly used on high pressure water jet technology like water cutting machines, hydro blasting pumps and turbines, hydrodemolition. The TIG welding between the case and the process socket, strengthens the instrument and assures a better tight in case of dampening fluid. The advantages of filling the case of the instrument with a dampening fluid are: reduced pointer fluctuation, reduced wear of rotating parts of the movement when pulsant vibrations and pulsations occur.

Moreover condensation and corrosive atmospheres which could damage the internal parts are prevented.

price by request

Bourdon tube pressure gauges anti-vibration version DS 4” (100mm)

Instruments designed for use on power units, pump, hydro-cleaning machines, presses, engine compressors, turbines, diesel engines, chemical, petrochemical and refrigerating plants and on machines and equipment where pulsating pressures or mechanical vibrations are apparent. They can be used with gaseous or liquid media which do not corrode copper alloy and which do not have high viscosity or do not cristalize.

price by request

Bourdon tube pressure gauges NACE MR0103/MR0175 – ISO 15156-3 version DS 4”, 6” (100-150mm)

These instruments are designed for petrochemical industry. They are built to resist to the most severe conditions created by H2S, by the environment and for those fluids, which have high viscosity and do not crystallize. The quality of the materials used to build the sensible element allows their use with high frequency pulsating pressures. The TIG welding between the case and the process socket, strengthens the instrument and assures a better tight in case of dampening fluid. The advantages of filling the case of the instrument with a dampening fluid are: reduced pointer fluctuation, reduced wear of rotating parts of the movement when pulsant vibrations and pulsations occur. Moreover condensation and corrosive atmospheres which could damage the internal

price by request