Products not found

The Mercoid® Series 3200G Explosion-Proof Pressure Transmitter is a microprocessor-based high performance transmitter, which has flexible pressure calibration, push button configuration, and programmable using HART® Communication. The Series 3200G is capable of being configured with the zero and span buttons, a field calibrator is not required for configuration. The transmitter software compensates for thermal effects, improving performance. EEPROM stores configuration settings and stores sensor correction coefficients in the event of shutdowns or power loss. The Series 3200G is FM approved for use in hazardous (Classified) locations. The 100:1 rangeability allows the smart transmitter to be configured to fit any application.

Retail price from 1304,1 €

The Series 3400 Smart Pressure Transmitter is a microprocessor-based high performance transmitter, which has flexible pressure calibration, push button configuration, and is programmable using HART® Communication. The Series 3400 is capable of being configured with the zero and span buttons (a field calibrator is not required for configuration). The transmitter software compensates for thermal effects, improving performance. EEPROM stores configuration settings and stores sensor correction coefficients in the event of shutdowns or power loss. The Series 3400 can be configured to be ATEX or IECEX approved for use in hazardous (classified) locations. The rangeability allows the smart transmitter to be configured to fit most applications.

Retail price from 1121,95 €

Gauge Pressure transmitters compare a pressure relative to atmospheric measure.

price by request

A pressure transmitter is a mechanical device that measures the expansive force of a liquid or gaseous sample.

Also known as a pressure transducer, this type of sensor is typically composed of a pressure sensitive surface area made of steel, silicon, or other materials depending upon the analyte’s composition. Behind these surfaces are electronic components capable of converting the applied force of the sample upon the pressure sensor into an electrical signal.

price by request

Differential Pressure (DP) is defined as the difference between two pressures. Differential Pressure Transmitters use a reference point called the low-side pressure and compare it to the high-side pressure. Ports in the instrument are marked high-side and low-side.

price by request

Differential Pressure (DP) is defined as the difference between two pressures. Differential Pressure Transmitters use a reference point called the low-side pressure and compare it to the high-side pressure. Ports in the instrument are marked high-side and low-side.

price by request

Differential Pressure (DP) is defined as the difference between two pressures. Differential Pressure Transmitters use a reference point called the low-side pressure and compare it to the high-side pressure. Ports in the instrument are marked high-side and low-side.

price by request

The Series 3500 Smart Differential Pressure Transmitter is a microprocessor-based high performance transmitter, which has flexible pressure calibration, push button configuration, and is programmable using HART® Communication. The Series 3500 is capable of being configured for differential pressure or level applications with the zero and span buttons. A field calibrator is not required for configuration. The transmitter software compensates for thermal effects, improving performance. EEPROM stores configuration settings and stores sensor correction coefficients in the event of shutdowns or power loss. The Series 3500 can be configured to be ATEX or IECEX approved for use in hazardous (classified) locations. The rangeability allows the smart transmitter to be configured to fit any application.

price by request

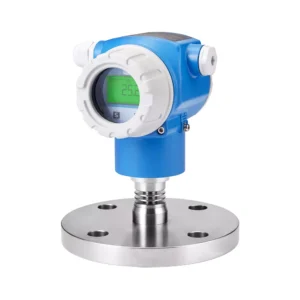

- SMART Transmitter 4-20mA + HART protocol

- Span limits : -1 to 100 bar

- Rangeability : 16:1

- Accuracy : 0.1%

- Power supply 10.5 to 45 VDC

- Process wetted parts material 316L stainless steel

- Process connection direct

- Burnout signal according NAMUR NE43 recommandations

- Long term stability : +/-0.1% of maximum span / 10years

Options: Local analog or digital Indicator; Intrinsically safe version; Explosion proof version; FM, CSA and IECEx certification; Stainless Steel electronic housing

price by request

- SMART Transmitter 4-20mA + HART protocol

- Span limits : 0 to 30 bar

- Rangeability : 16:1

- Accuracy : 0.2%

- Power supply 10.5 to 45VDC

- Process wetted parts material 316L stainless steel

- Process connection direct

- Burnout according NAMUR NE43 recommandations

- Long term stability : +/- 0.1% of maximum span / 10years

Options: Local analog or digital indicator, Intrinsically safe version, Explosion proof version, FM, CSA and IECEx certification, Stainless Steel electronic housing.

price by request

- SMART Transmitter 4-20mA + HART protocol

- Span limits : 0.1 KPa to 20000KPa

- Rangeability : 100:1

- Accuracy : 0.065% (0.04% as an option)

- Power supply 10.5 to 45VDC

- Process wetted parts material : Inox 316L, Hastelloy, Monel, Tantalum,

- Process connection : ¼”-18NPT (oval flanges on request)

- Burnout according NAMUR NE43 recommandations

- Long term stability : +/- 0.1% of maximum span / 10years

Options: Local analog or digital Indicator, Intrinsically safe version, Explosion proof version, FM, CSA and IECEX certification.

» Stainless Steel electronic housing

price by request

- SMART Transmitter, -20mA + HART protocol

- Span limits: 0 to 100 bar

- Rangeability : 100:1

- Accuracy : 0.2% (0.1% as an option)

- Power supply 10.5 to 45VDC

- Process wetted parts material: 316L st. st., Hastelloy, Monel, Tantalum,

- Process connection ¼”-18NPT (oval flanges on request)

- Burnout according NAMUR NE43 recommandations

- Long term stability : +/- 0.1% of maximum span / 10years

Options: Local analog or digital indicator, Intrinsically safe version, Explosion proof version, FM, CSA and IECEx certification, Stainless Steel electronic housing

price by request

Gauge Pressure transmitters compare a pressure relative to atmospheric measure.

price by request

Gauge Pressure transmitters compare a pressure relative to atmospheric measure.

price by request

Gauge Pressure transmitters compare a pressure relative to atmospheric measure.

price by request

Gauge Pressure transmitters compare a pressure relative to atmospheric measure.

price by request