Made in Germany. brand Leitenberger, model LDW-H

Fast delivery to Latvia, Estonia and Lithuania. International delivery to Europe, Asia, Africa and other continents available on request

Our warehouse is located in Riga, Latvia.

Retail price from 3 414 €

Available

Official distributor in Latvia

Time-tested American, European and Asian brands of control and measurent instruments

Special price list for organisations

We offer a significant discount for trade organisations and manufacturing companies

Worldwide shipping on request

We take care of all logistics and customs clearance. Fast delivery to Baltic countries

After-sales service and support

Warranty service and repair, expert assistance in the operation of the instruments

Proven primary standard

Pressure balances (deadweight tester) are the most accurate devices available on the market for the calibration of electronic or mechanical pressure measuring instruments. The direct measurement of the pressure (p = F/A), as well as the use of high quality materials allow a very small measurement uncertainty in combination with an excellent long-term stability of 5 years (recommendation according to the German Calibration Service (DAkkS). Pressure balances / deadweight tester have been used for years in factory and calibration laboratories of industry, national institutes and research institutes.

Autonomous mode of operation

Due to the integrated pressure generation as well as the purely mechanical measuring principle, the LR-Cal LDW-H deadweight tester is also ideally suited for on-site use, maintenance and service.

Basic principle

Pressure is defined as the quotient of force and area. Accordingly, the heart of the LR-Cal LDW-H pressure balance is a very precisely manufactured piston/cylinder system, which is loaded with mass supports to generate the individual test points.

The mass support is proportional to the target pressure and is achieved by optimally graduated disc weights. These disc weights are manufactured as standard to the standard acceleration of gravity of 9.80665 m/s², but can also be optionally adapted to their specific location of use and also DAkkS-calibrated.

Simple mode of operation

In the sturdy basic unit, even large test volumes can be easily filled and compressed with the integrated pre-pressure pump and 250 ml tank. For further pressure build-up, a very precisely adjustable spindle pump with internal rotating spindle is installed.

As soon as the measuring system is in a floating state, there is a balance of forces between the pressure and the mass supports. Due to the excellent workmanship of the system, this pressure remains stable for several minutes, so that the pressure values for comparative measurement or even more extensive adjustment work can be carried out on the test specimen without any problems.

Two basic unit versions

The LR-Cal LDW-H deadweight tester is available in two versions, both with integrated pressure supply:

The test specimen is connected to a quick-connect system without tools. Due to the free-running knurled nut, the test specimens can be aligned as required. A threaded insert with a 1/2″ BSP female thread is included as standard. Further threaded inserts are optionally available, with which all common pressure gauges can be connected.

Special features:

Applications:

Single piston pressure ranges:

| Measuring Range 1) | bar, kg/cm² | 1…120 | 2…300 |

|---|---|---|---|

| Required masses | kg | 49.7 | 49.6 |

| Smallest step 2) standard set of masses | bar, kg/cm² | 0.5 | 2.5 |

| Smallest step 3) optional fine increment weights | bar, kg/cm² | 0.02 | 0.05 |

| Nominal cross-sectional area of the piston | cm² | 0.4032 | 0.1613 |

| Measuring Range 1) | psi, lb/in² | 10…1,600 | 30…4,000 |

| Required masses | kg | 45.5 | 45.3 |

| Smallest step 2) standard set of masses | psi, lb/in² | 5 | 20 |

| Smallest step 3) optional fine increment weights | psi, lb/in² | 0.2 | 0.5 |

| Nominal cross-sectional area of the piston | cm² | 0.4032 | 0.1613 |

| Measuring Range 1) | kPa | 100…12,000 | 200…30,000 |

| Required masses | kg | 49.7 | 49.6 |

| Smallest step 2) standard set of masses | kPa | 50 | 250 |

| Smallest step 3) optional fine increment weights | kPa | 2 | 5 |

| Nominal cross-sectional area of the piston | cm² | 0.4032 | 0.1613 |

| Accuracy | |||

| Standard 4) 5) | % of measured value |

0.015 | 0.015 |

| Optional 4) 5) | % of measured value |

0.007 | 0.006 |

| Pressure transmission medium | |||

| Standard | Hydraulic fluid based on mineral oil | ||

| Optional | Sebacate oil Brake fluid Skydrol Fomblin oil |

||

| Material | |||

| Piston | Steel | Steel | |

| Cylinder | Bronze | Steel | |

| Set of masses | Stainless steel, non-magnetic | ||

| Weights | |||

| Piston-cylinder system | kg | 1 | 0.8 |

| Storage case for piston-cylinder system | kg | 3.1 | 3.1 |

| “bar” standard mass sets (in 2 cases) | kg | 61.3 | 61.2 |

| “psi” standard mass sets (in 2 cases) | kg | 57.1 | 56.9 |

| Optional “bar” fine increment masses | kg | 0.33 | 0.5 |

| Optional “psi” fine increment masses | kg | 0.23 | 0.34 |

| Dimensions | |||

| Carrying case for standard mass sets | mm | W 400 x D 310 x H 310 | |

| Optional storage case for piston-cylinder systems | mm | W 300 x D 265 x H 205 | |

Double piston pressure ranges:

| Measuring Range 1) | bar, kg/cm² | 1…60 / 10…700 | 1…60 / 20…1.200 | 1…60 / 20…1.400 |

|---|---|---|---|---|

| Required masses | kg | 57.4 | 49.2 | 57.4 |

| Smallest step 2) standard set of masses | bar, kg/cm² | 0.5 / 5.0 | 0.5 / 10 | 0.5 / 10 |

| Smallest step 3) optional fine increment masses | bar, kg/cm² | 0.01 / 0.1 | 0.01 / 0.2 | 0.01 / 0.2 |

| Nominal cross-sectional area of the piston | cm² | 0.8065 / 0.0807 | 0.8065 / 0.0403 | 0.8065 / 0.0403 |

| Measuring Range 1) | psi, lb/in² | 10…800 / 100…10,000 | 10…800 / 200…16,000 | 10…800 / 200…20,000 |

| Required masses | kg | 56.4 | 45 | 56.4 |

| Smallest step 2) standard set of masses | psi, lb/in² | 5 / 50 | 5 / 100 | 5 / 100 |

| Smallest step 3) optional fine increment masses | psi, lb/in² | 0.1 / 1 | 0.1 / 2 | 0.1 / 2 |

| Nominal cross-sectional area of the piston | cm² | 0.8065 / 0.0807 | 0.8065 / 0.0403 | 9.8065 / 0.0403 |

| Measuring Range 1) | kPa | 100…6,000 / 1,000…70,000 | 100…6,000 / 2,000…120,000 | 100…6,000 / 2,000…140,000 |

| Required masses | kg | 57.4 | 49.2 | 57.4 |

| Smallest step 2) standard set of masses | kPa | 50 / 500 | 50 / 1,000 | 50 / 1,000 |

| Smallest step 3) optional fine increment masses | kPa | 1 / 10 | 1 / 20 | 1 / 20 |

| Nominal cross-sectional area of the piston | cm² | 0.8065 / 0.0807 | 0.8065 / 0.0403 | 0.8065 / 0.0403 |

| Accuracy | ||||

| Standard 4) 5) | % of measured value |

0.015 | 0.015 | 0.025 |

| Optional 4) 5) | % of measured value |

0.006 | 0.007 | 0.007 |

| Pressure transmission medium | ||||

| Standard | Hydraulic fluid based on mineral oil | |||

| Optional | Sebacate oil Brake fluid Skydrol Fomblin oil |

Sebacate oil Brake fluid Skydrol Fomblin oil |

Sebacate oil | |

| Material | ||||

| Piston | Tungsten carbide / steel | Tungsten carbide /steel | Tungsten carbide / steel | |

| Cylinder | Steel / Tungsten carbide | Steel / Tungsten carbide | Steel / tungsten carbide | |

| Set of masses | Stainless steel, non-magnetic | |||

| Weight | ||||

| Piston-cylinder system | kg | 2 | 2 | 2 |

| Storage case for piston-cylinder system (optional) | kg | 3,1 | 3,1 | 3,1 |

| “bar” standard set of masses (in 2 wooden cases) | kg | 69 | 60,8 | 69 |

| “psi” standard set of masses (in 2 wooden cases) | kg | 68 | 56,6 | 68 |

| Optional “bar” fine increment masses | kg | 0,5 | 0,5 | 0,5 |

| Optional “psi” fine increment masses | kg | 0,34 | 0,34 | 0,34 |

| Dimensions | ||||

| Carrying case for standard mass sets | mm | B400 x T310 x H310 | ||

| Optional storage case for piston-cylinder systems | mm | B300 x T265 x H205 | ||

1) Theoretical starting value; corresponds to the pressure value generated by the piston or the piston and its make-up weights (bei their own weight). To optimise the operating characteristics more weights should be loaded.

2) The smallest pressure change value that can be achieved based on the standard weight set. To reduce this, a set of trim masses is also available. See Accessories.

3) The smallest pressure change value that can be achieved based on the optional fine increment weights. For further reductions, an accessory of class M1 or F1 trimm masses is available.

4) The accuracy from 10% of the measuring range is based on the measured value. In the lower range, the accuracy is 0.03% of reading for single-range piston-cylinder-systems and 0.025% of reading for dual-range piston-cylinder-systems.

5) Measuring uncertainty assuming reference conditions (ambient temperature 20°C, air pressure 1,013 mbar, relative humidity 40%).Corrections mus be made if required.

| Photo | Model | Description |

|---|---|---|

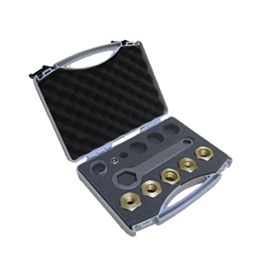

|

LDW-H-KOFFER-KZS | Transport and storage case for the piston cylinder system |

|

LDW-FMS-F1 | Fine incremental weight set class F1 1 mg bis 50 g |

|

LDW-FMS-M1 | Fine incremental weight set class M1 1 mg bis 50 g |

|

LDW-ADAPTER-BSP | Set of BSP adapter for test item port to 1/2″ + 1/4″ + 3/8″ + 1/2″ BSP |

|

LDW-ADAPTER-NPT | Set of NPT adapter for test item port to 1/8″ + 1/4″ + 3/8″ + 1/2″ NPT |

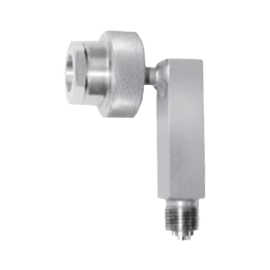

|

CPB5000-WA90 | 90° elbow connector e.g. for connecting pressure gauges with rear pressure connection to the test connection of the deviceLDW-TV-M-1200 |

|

LDW-TV-M-0700 | Separator max. 700 bar with membrane. To separate the media of the test specimen and the device |

|

LDW-TV-M-1200 | Separator max. 1,200 bar with membrane To separate the media of the test specimen and the device |

| Model | Description | Price |

|---|---|---|

| LDW-H-S-OL | Basement LR-Cal LDW-H – hydraulic, max. 1.200 bar / max. 17.400 psi, operating fluid: mineral oil | 3414 $ |

| LDW-H-S-SO | Basement LR-Cal LDW-H – hydraulic, max. 1.200 bar / max. 17.400 psi, operating fluid: sebacate oil | 3414 $ |

| LDW-H-S-BF | Basement LR-Cal LDW-H – hydraulic, max. 1.200 bar / max. 17.400 psi, operating fluid: brake fluid | 5165 $ |

| LDW-H-S-SD | Basement LR-Cal LDW-H – hydraulic, max. 1.200 bar / max. 17.400 psi, operating fluid: skydrol | 5165 $ |

| LDW-H-S-FO | Basement LR-Cal LDW-H – hydraulic, max. 1.200 bar / max. 17.400 psi, operating fluid: fomblin oil | 5165 $ |

| LDW-H-H-OL | Basement LR-Cal LDW-H – hydraulic, max. 1.400 bar / max. 20.300 psi, operating fluid: mineral oil | 4868 $ |

| LDW-H-H-SO | Basement LR-Cal LDW-H – hydraulic, max. 1.400 bar / max. 20.300 psi, operating fluid: sebacate oil | 4868 $ |

| LDW-H-EKZ-0120-G15 | Systeme piston-cylinder. Range 1…120 (bar or equivalent). Standard: ±0,015% | 2200 $ |

| LDW-H-EKZ-0300-G15 | Systeme piston-cylinder. Range 2…300 (bar or equivalent). Standard: ±0,015% | 2500 $ |

| LDW-H-DKZ-0700-G15 | Systeme piston-cylinder. Range 1…60 + 10…700 (bar or equivalent). Standard: ±0,015% | 4400 $ |

| LDW-H-DKZ-1200-G15 | Systeme piston-cylinder. Range 1…60 + 20…1200 (bar or equivalent). Standard: ±0,015% | 5100 $ |

| LDW-H-DKZ-1400-G25 | Systeme piston-cylinder. Range 1…60 + 20…1400 (bar or equivalent). Standard: ±0,015% | 5400 $ |

| LDW-H-EKZ-0120-G07 | Systeme piston-cylinder. Range 1…120 (bar or equivalent). PREMIUM: ±0,007% | 3500 $ |

| LDW-H-EKZ-0300-G06 | Systeme piston-cylinder. Range 2…300 (bar or equivalent). PREMIUM: ±0,007% | 3900 $ |

| LDW-H-DKZ-0700-G06 | Systeme piston-cylinder. Range 1…60 + 10…700 (bar or equivalent). PREMIUM: ±0,007% | 7460 $ |

| LDW-H-DKZ-1200-G07 | Systeme piston-cylinder. Range 1…60 + 20…1200 (bar or equivalent). PREMIUM: ±0,007% | 8200 $ |

| LDW-H-DKZ-1400-G07 | Systeme piston-cylinder. Range 1…60 + 20…1400 (bar or equivalent). PREMIUM: ±0,007% | 8500 $ |

| LDW-H-MS-0120 | Basic mass set LR-Cal LDW-H-MS. Range 1…120 (bar or equivalent) | 2940 $ |

| LDW-H-MS-0300 | Basic mass set LR-Cal LDW-H-MS. Range 2…300 (bar or equivalent) | 2940 $ |

| LDW-H-MS-0700 | Basic mass set LR-Cal LDW-H-MS. Range 1…60 + 10…700 (bar or equivalent) | 3200 $ |

| LDW-H-MS-1200 | Basic mass set LR-Cal LDW-H-MS. Range 1…60 + 20…1200 (bar or equivalent) | 3500 $ |

| LDW-H-MS-1400 | Basic mass set LR-Cal LDW-H-MS. Range 1…60 + 20…1400 (bar or equivalent) | 3900 $ |

| LDW-H-FMS-0120 | Increment weights LR-Cal LDW-H-FMS. Range 1…120 (bar or equivalent) | 670 $ |

| LDW-H-FMS-0300 | Increment weights LR-Cal LDW-H-FMS. Range 2…300 (bar or equivalent) | 670 $ |

| LDW-H-FMS-0700 | Increment weights LR-Cal LDW-H-FMS. Range 1…60 + 10…700 (bar or equivalent) | 670 $ |

| LDW-H-FMS-1200 | Increment weights LR-Cal LDW-H-FMS. Range 1…60 + 20…1200 (bar or equivalent) | 670 $ |

| LDW-H-FMS-1400 | Increment weights LR-Cal LDW-H-FMS. Range 1…60 + 20…1400 (bar or equivalent) | 670 $ |

You can request the necessary certificates, documentation, instructions and user guide for Leitenberger LDW-H using the special form.

You can buy Leitenberger LDW-H in Latvia at a price starting from 3414 € in «OLIL SIA» by leaving a request on the website, by phone +371 672 70580 or by email olil@olil.lv. Leitenberger LDW-H price are subject to change depending on exchange rates. We deliver instruments by transport companies in Latvia, Estonia and Lithuania. Worldwide shipping to Europe, Asia, Africa, North and South America available on request.

See also: Deadweight testers